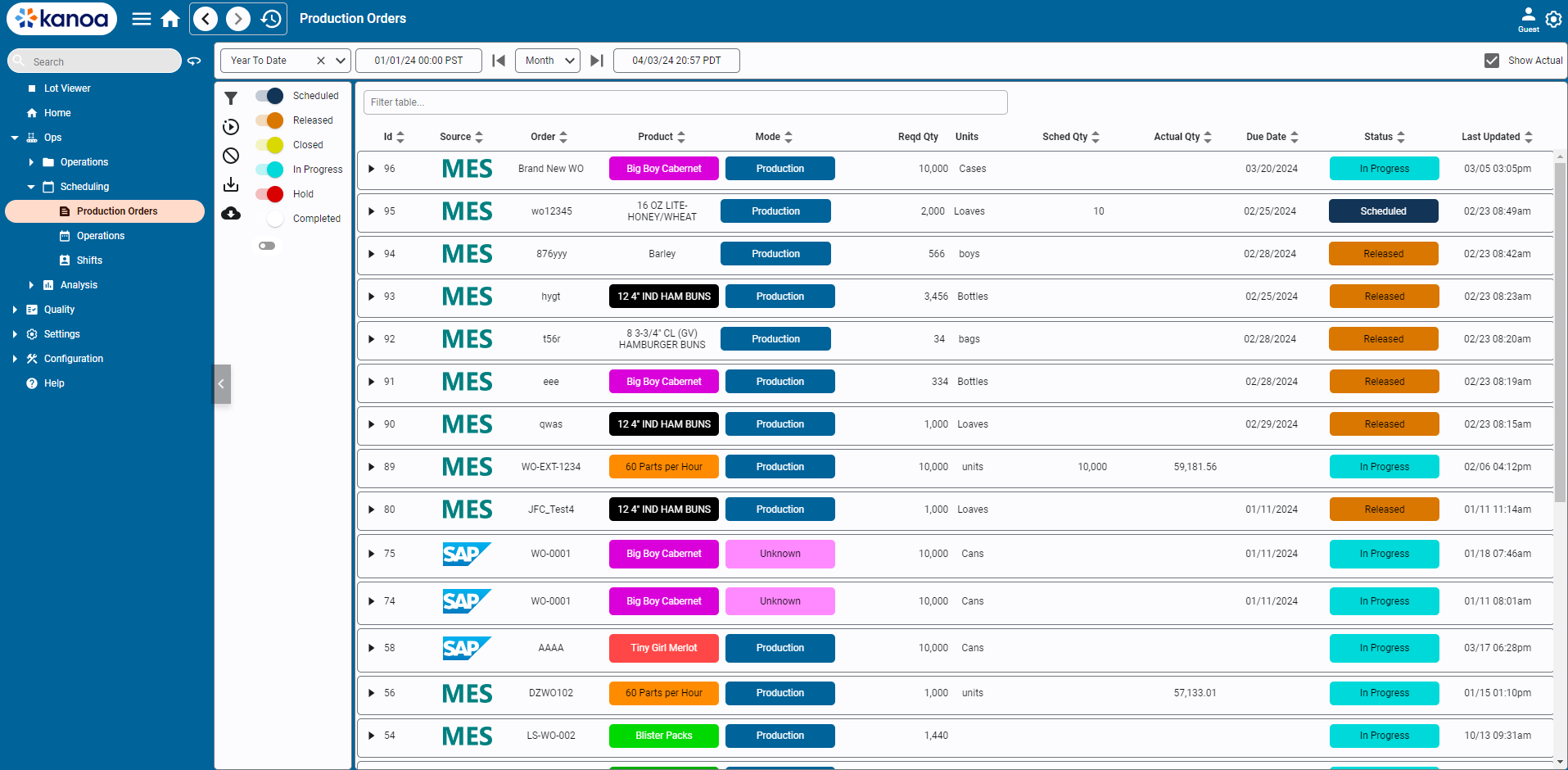

Order Management

Whether you call them Production Orders, Manufacturing Orders, Work Orders, or Batch Tickets, this screen provides you with the ability to view, create and edit orders to build products on your assets. You can also view orders from your ERP once the two systems are connected. This can all be done via web services or middleware tables.

Filtering

Orders can be filtered by due date and status. If an order does not have a due date set, it will be included regardless of the date range selected. The state filter button toggles the state selector.

The Show Actual checkbox displays the actual quantities produced for a production order, whether the order was run once or across multiple runs on multiple assets. Enabling this will slow down the query as it will look for all production runs against this production order.

Order States

The following order states are considered 'reserved' in our system, but you can also create your own.

- Released: The order has been released to production.

- Hold: A hold has been placed on this order.

- In Progress: There are active runs in progress on this order or this order has been partially completed. The first time a production run is started against an order, MES will change the state to 'In Progress'.

- Completed: This production order has been completed.

- Closed: This production order has been closed.

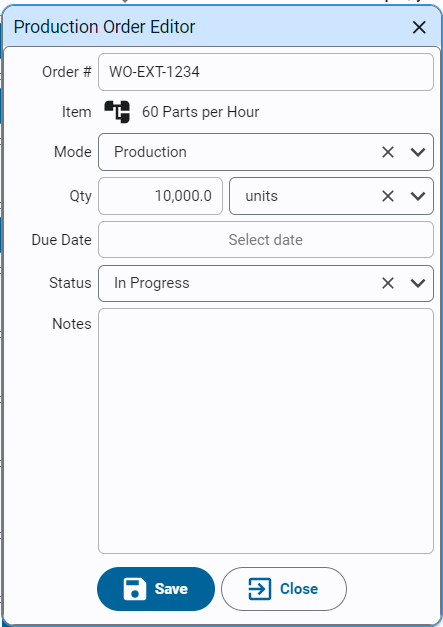

Adding & Editing Orders

Click the '+' button to add a new production order.

To edit an existing order, select it in the table and click .

- Order #: Enter a unique identifier for this order.

- Item: Use the item selector to select the item (product) to be made.

- Qty: The required amount to be produced.

- Units: Ideally, the units here will be the same as the units configured for this asset-item in the production rate configuration screen.

- Due Date: Date this order needs to be completed by (optional).

- Status: The state of this Order, whether it has been released to production or is held. When an operation starts for this work order, the system automatically sets the status to 'In Progress'.

- Notes: Any notes you want to share with the folks running this order.

To delete an order, select it in the table and click .

Production Order Metadata

In addition to the standard fields required to create and schedule a Production Order, Kanoa MES supports Production Order Metadata as a flexible and extensible mechanism for associating additional business-specific information with an order.

Production Order Metadata is designed to support the reality that many manufacturers require more contextual data than what is captured in a baseline production order. This may include information such as:

- Bill of Materials (BOM)

- Startup or pre-flight checklists

- Machine setpoints

- API payloads or integration messages

- Custom instructions or configuration data used by extensions or automation

Rather than enforcing a rigid schema, Kanoa allows any number of metadata entries to be attached to a production order.

Metadata Structure

Each Production Order Metadata entry consists of:

metaDataName

A common, human-readable identifier used to describe and retrieve the metadata

(for example:BOM,apiBody,Startup Checklist,Machine Setpoints).metaDataValue

The data payload associated with that metadata name.

This value is stored as a string and may contain plain text, Markdown, or structured data such as JSON.workOrderId

The work order that this metadata is associated to.

While metadata values are not limited to any specific format, JSON strings are one of the most common and recommended approaches, as they allow complex, structured data to be associated with an order in a predictable and machine-readable way.

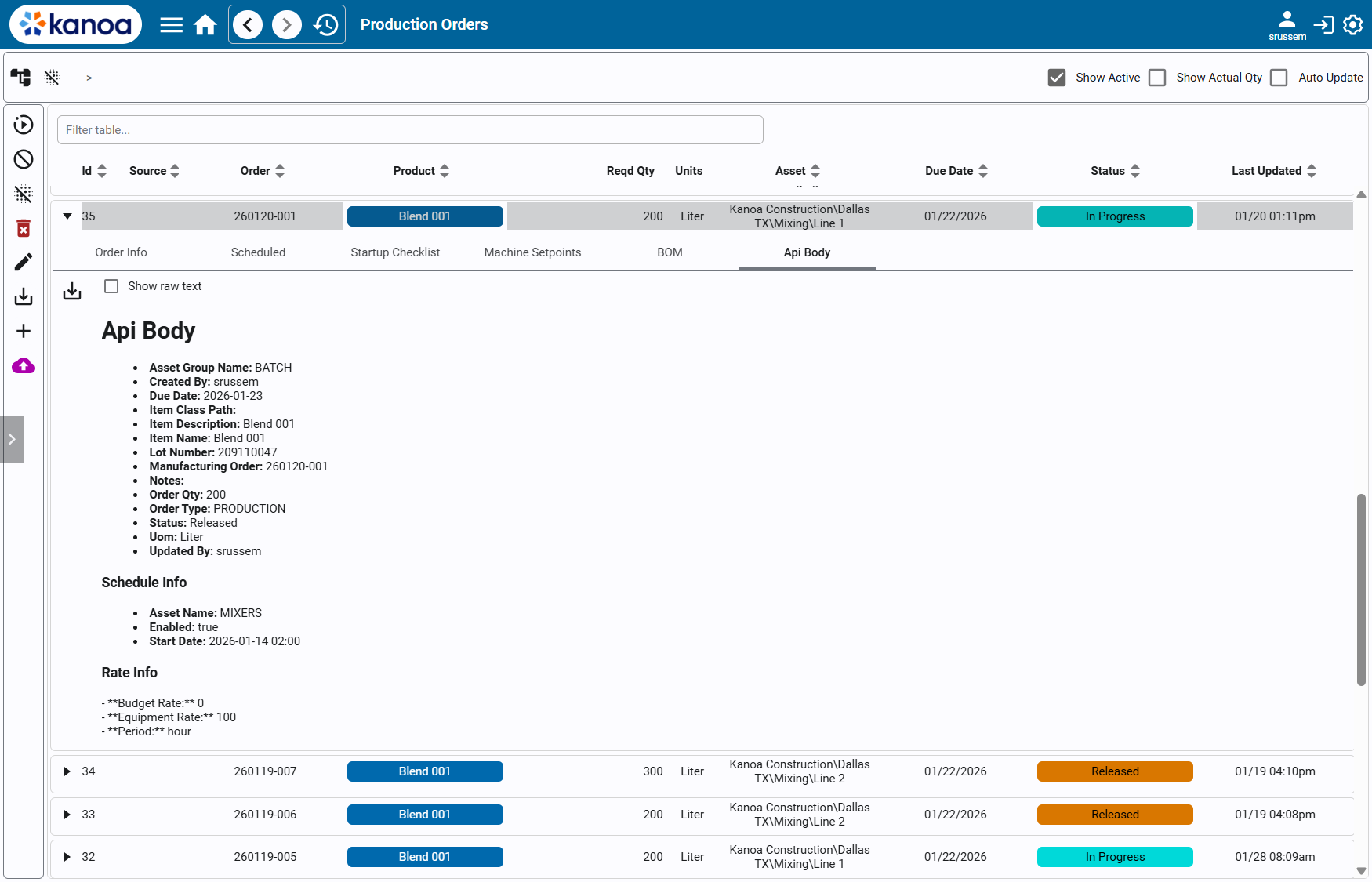

Viewing Metadata in the Application

Production Order Metadata can be viewed directly from the Production Orders screen.

- Click the left-hand expand arrow on a production order row to reveal additional details.

- The expanded view displays:

- Standard Order Info

- Schedule Info

- One tab per metadata entry associated with the order

- Each metadata tab is labeled using the metadata name.

Within a metadata tab, you may toggle Show raw text:

- When enabled, the raw metadata value is displayed exactly as stored.

- When disabled, Kanoa assumes the value contains Markdown (or JSON-compatible Markdown) and renders it using the built-in Markdown viewer for improved readability.

This makes metadata well-suited for both machine consumption and operator-facing visualization.

Programmatic Access & Extensibility

Production Order Metadata is commonly used when implementing custom extensions, integrations, or business logic within Kanoa MES.

Metadata can be:

- Added when an order is created

- Updated over the lifecycle of an order

- Retrieved by name, order, or status

- Deleted when no longer needed

This enables developers and integrators to:

- Drive custom workflows based on metadata content

- Pass structured data between systems

- Attach configuration or instructions without modifying the core order schema

Kanoa provides system functions to add, update, retrieve, and delete production order metadata, allowing metadata to be fully managed through scripting and APIs.