Scheduling Operations

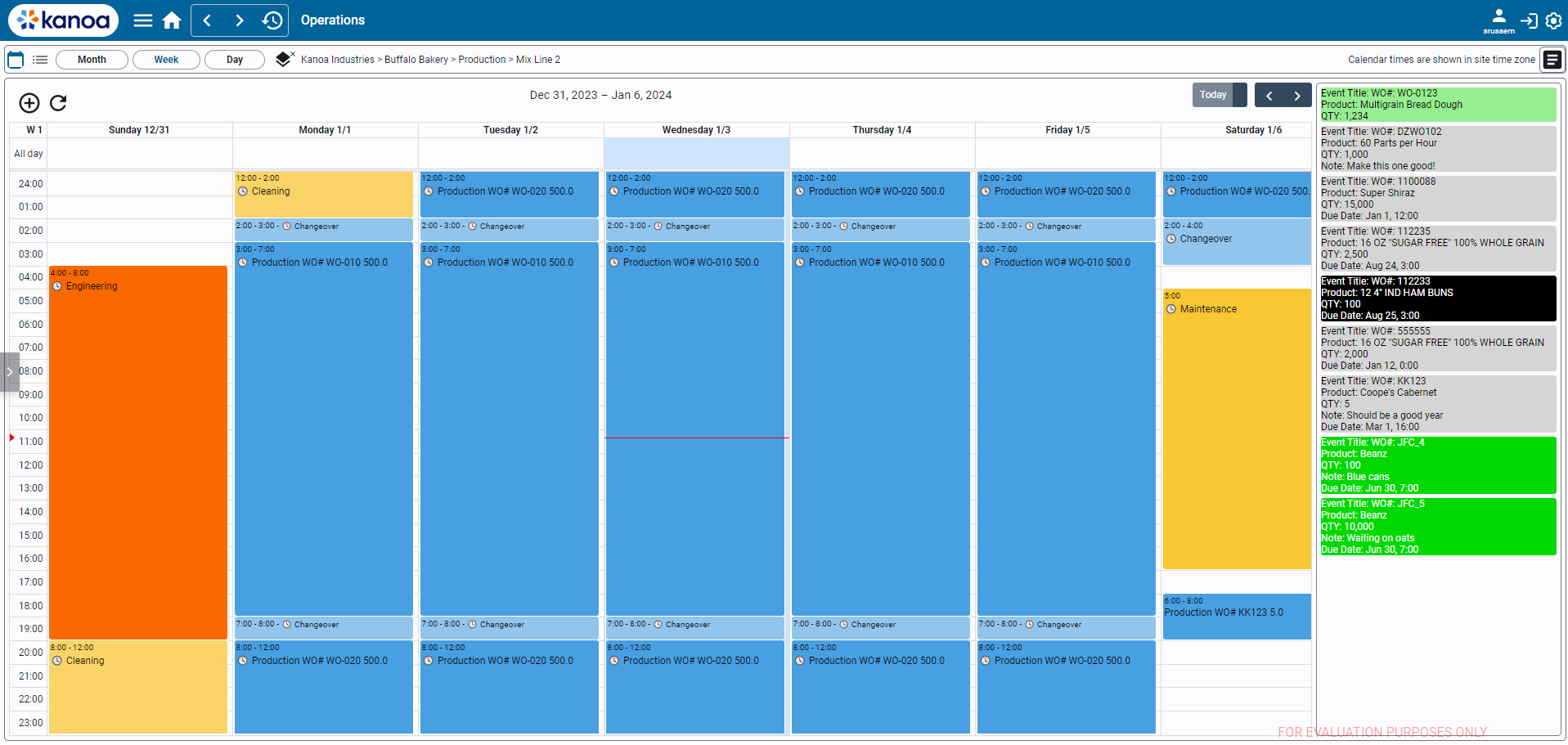

The operations schedule provides everyone in your organization with a clear view of current and planned activities. To truly gain deep insight into how your assets are being used, schedule information is crucial, and we strongly recommend that while you may have a different solution for scheduling and planning, whether that is done in ERP or Excel, that information needs to be shared with MES. Why? Because analyzing the performance of your manufacturing data is only useful when contextualized. Keeping scheduling information separate from production data limits your ability to answer the question: 'How well are we scheduling?' In fact, poor scheduling of resources in terms of asset, material, and personnel may well be your number one cause of inefficiency. Whether you use our built-in scheduling solution or a third party, integrating production scheduling information into the MES application is an important step in driving continuous improvement.

We use the BIJC Calendar component, thanks to Chris Taylor and Lewis Storey for this Ignition implementation of fullcalendar.io. For more information on this component please refer to the BIJC Calendar.

Features

Site Time Zone Support

KanoaOPS provides support for enterprises with sites in different time zones. When a site is selected, the calendar will show scheduled event times in the site's time zone.

You can set a sites time zone in the [asset configuration screen](/configuration/assets). A time zone selector drop-down is displayed for assets of type 'site'. Time zone is stored as a custom asset attribute called 'tz'.

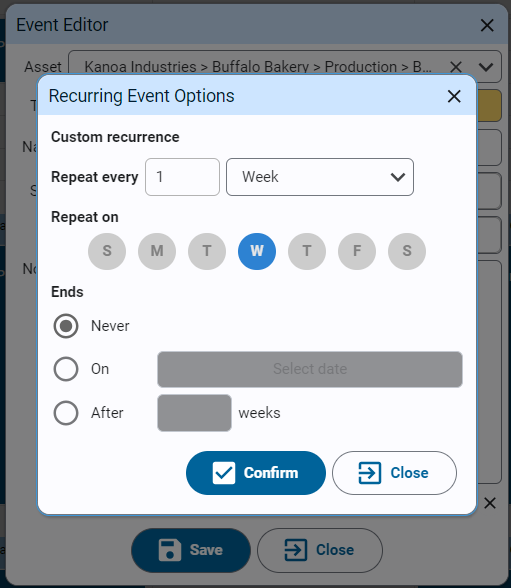

Recurring Events

We use the dateutil rrule object which offers a complete and fast implementation of the recurrence rules documented in the iCalendar RFC.

This makes the scheduling of repeating operations and shifts very simple and nearly identical to how it is done in Google Calendar, iCalendar, and Microsoft Outlook.

Auto Scheduling

When enabled, an asset is constantly checking for scheduled events. Whenever an operation ends, if any event such as maintenance or changeover has been scheduled, the asset is automatically set to the scheduled event mode. When the scheduled event ends, the asset will be set to an idle mode. The source of the mode, whether it was set by the PLC, an operator or the schedule, is stored along with the mode event. This information is what drives insights into asset utilization in that actual non-production events are captured rather than just seeing the asset in a production or idle mode.

The auto-schedule will only set the asset mode from the schedule when the current mode has not been set by the PLC or by an operator.

Auto-scheduling configuration is set in the Asset Mode Link. Additionally the tag [Kanoa]kanoa/mes/config/schedule/endScheduledRuns determines whether a scheduled Production run should be ended automatically or by the PLC or operator.

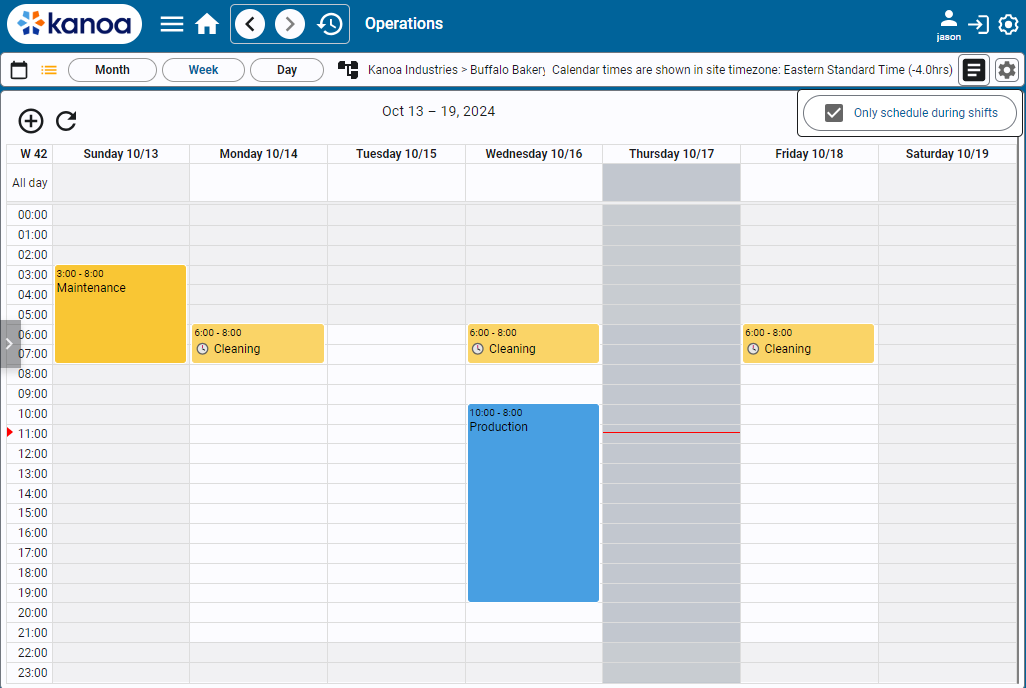

Shift Adherence

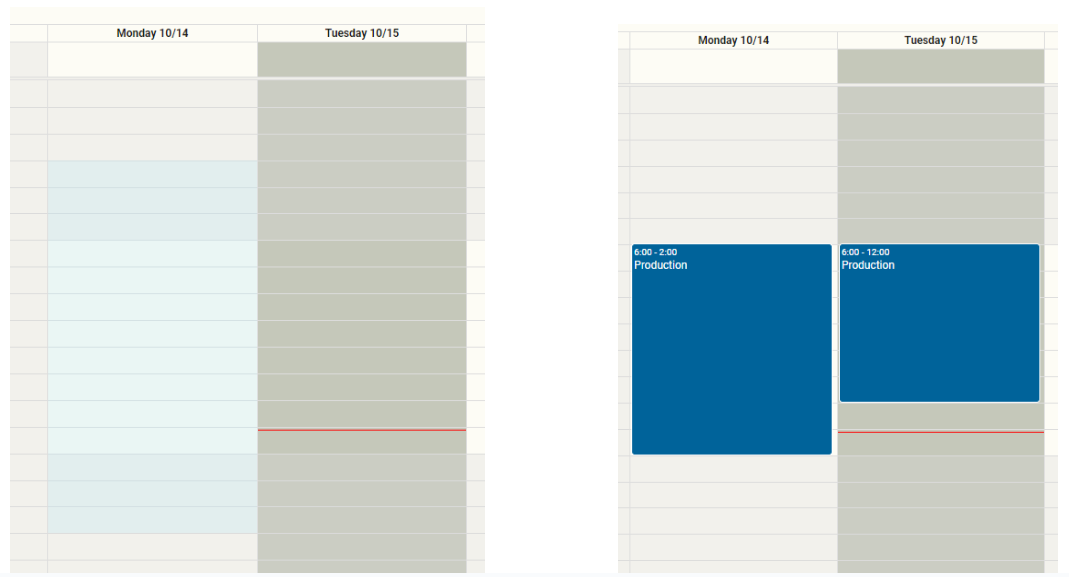

Shift adherence is a setting that dictates whether scheduled operations will be adjusted to conform with the asset's shift schedule. This setting is changed via the settings popup on the top right with a gear icon. When shift adherence is disabled, events can be scheduled at any time. Shift times are indicated on the calendar by the white sections.

If shift adherence is enabled, any operation that is scheduled will be forced to fit within the shift times.

If an operation is scheduled to start before the start of a shift, its start time will be adjusted to start at the earliest possible time.

If an operation is scheduled for longer than can be done in one event, the operation will be split into multiple events that are scheduled at their earliest possible time.

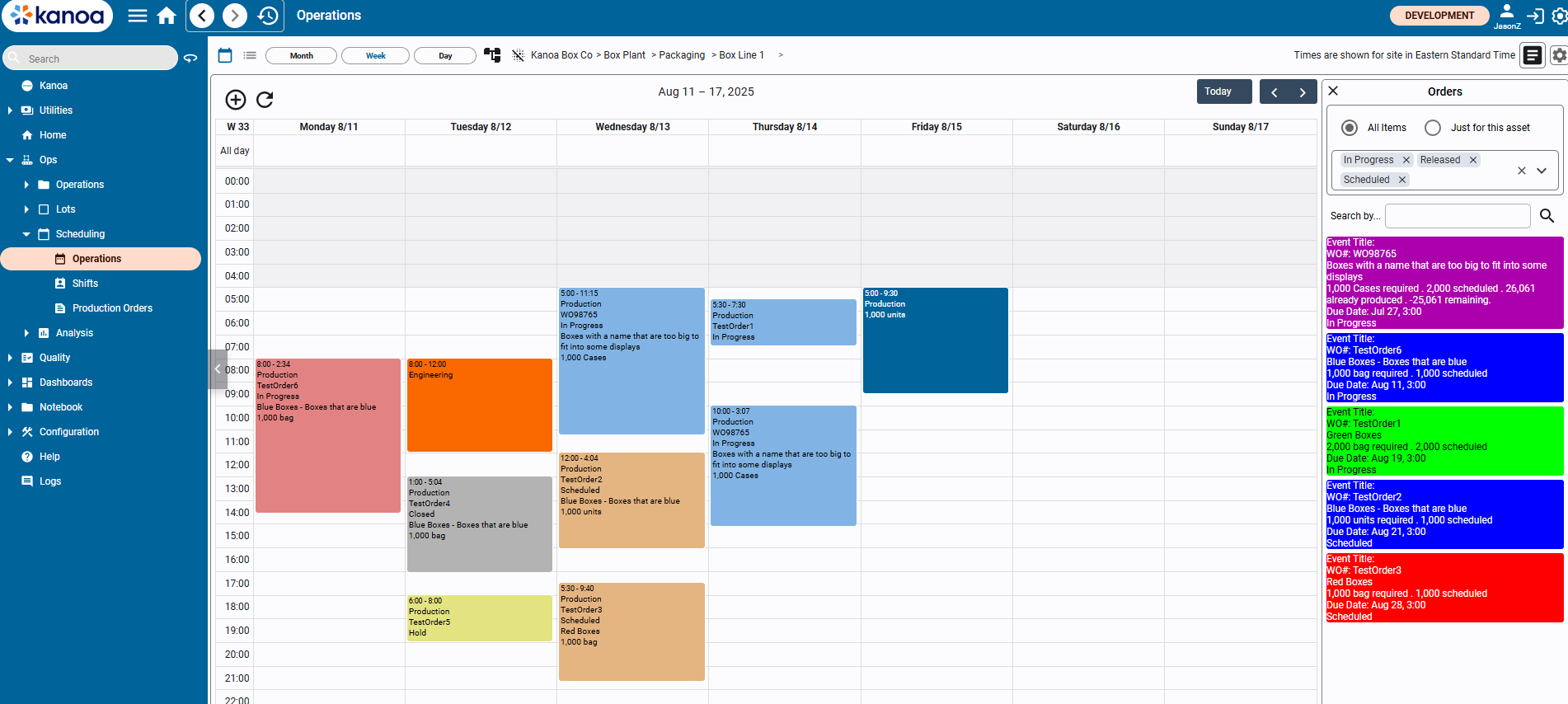

Order Status Color Configuration

When we schedule production orders on the calendar, our application allows for color coding the events by order status, for better recognition at a glance.

Here for example, we can see that orders that are “In Progress” are colored light blue, the orders that are ‘Scheduled’ are sand-colored, an order that is ‘Closed’ is grey, and so on. These colors will override how the orders would’ve been otherwise colored.

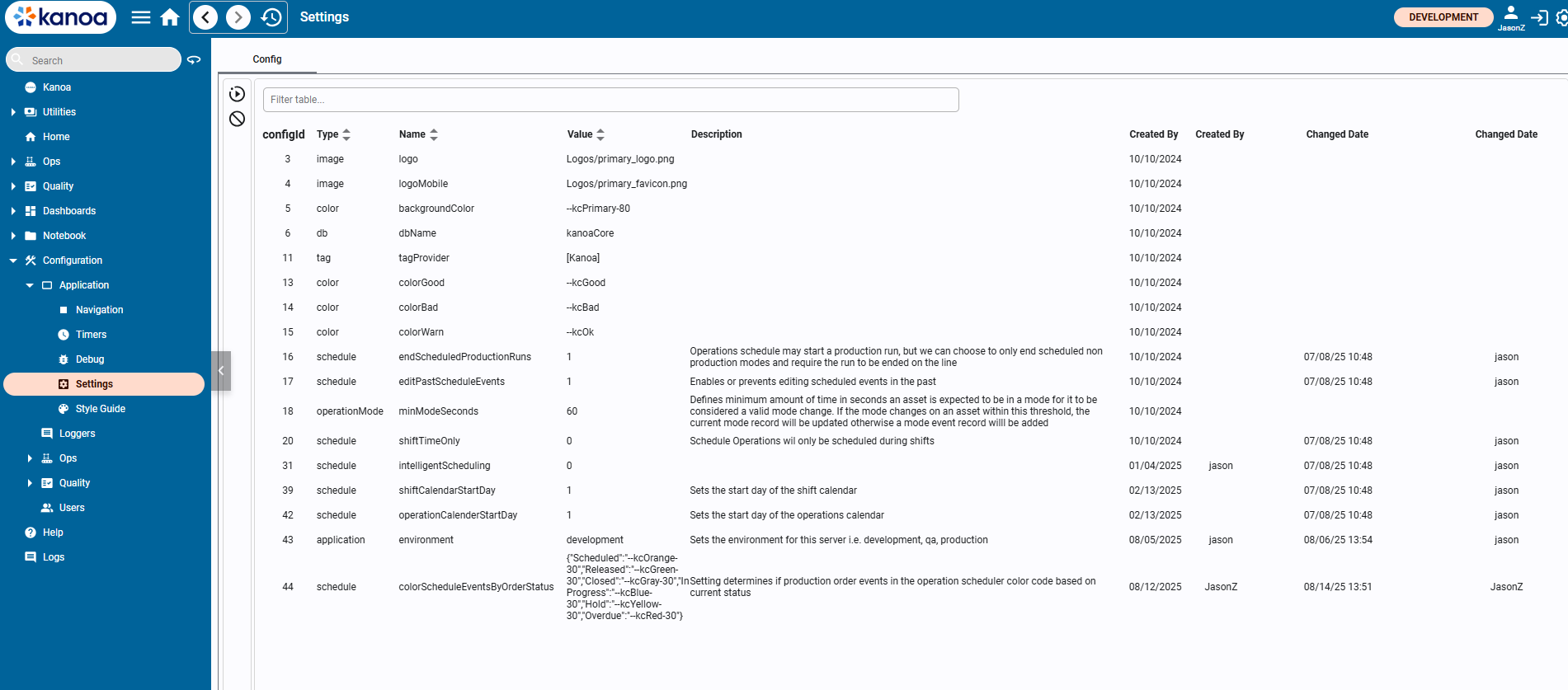

In order to configure this, we go to the application settings and look at the setting called ‘colorScheduleEventsByOrderStatus’.

In the value, we have a dictionary string, that represents a mapping of order statuses to colors. We have Scheduled, Released, Closed, In Progress, and Hold as our order statuses. Overdue is a special order status that isn’t directly stored in the database, but is determined by certain factors. In order to update the value of the dictionary correctly, make sure that the order status name and value are correctly enclosed in double string quotes, like: “Scheduled”:”--kcOrange30”. Valid values for colors are hex colors like #eb4034 or our Kanoa color variables.

As mentioned, Overdue is a special order status that is determined based on the order. If an order’s status is In Progress, Released, or Scheduled, its produced quantity is still lower than the scheduled quantity, and the current date is past the order’s due date, then the order is considered Overdue.

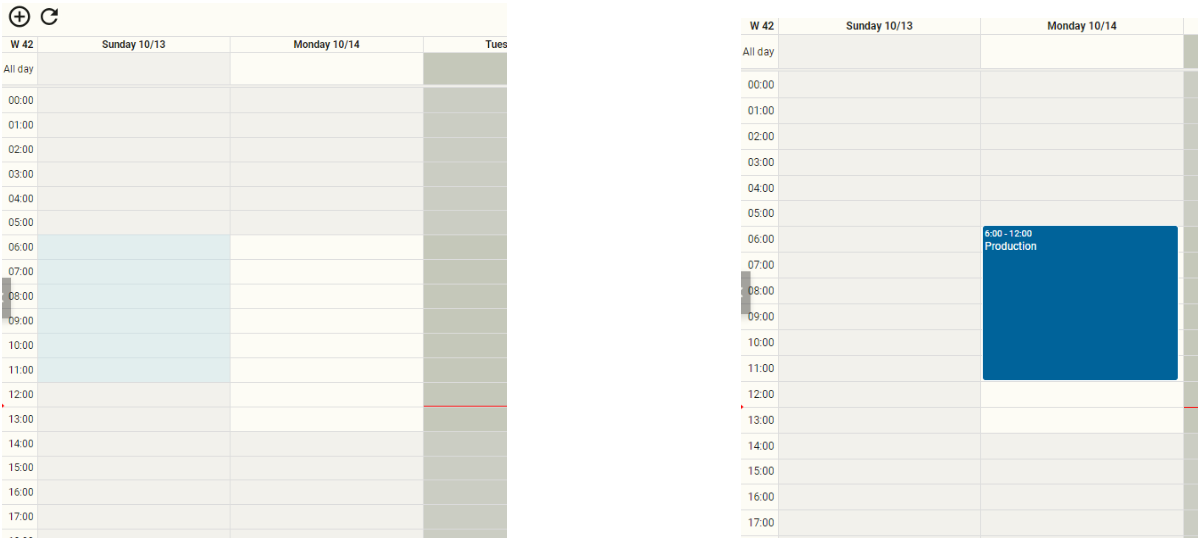

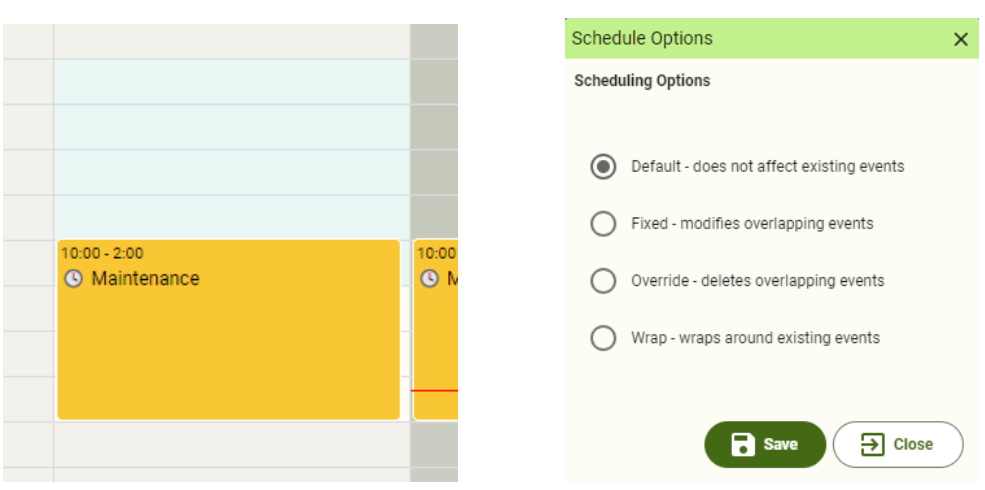

Intelligent Scheduling

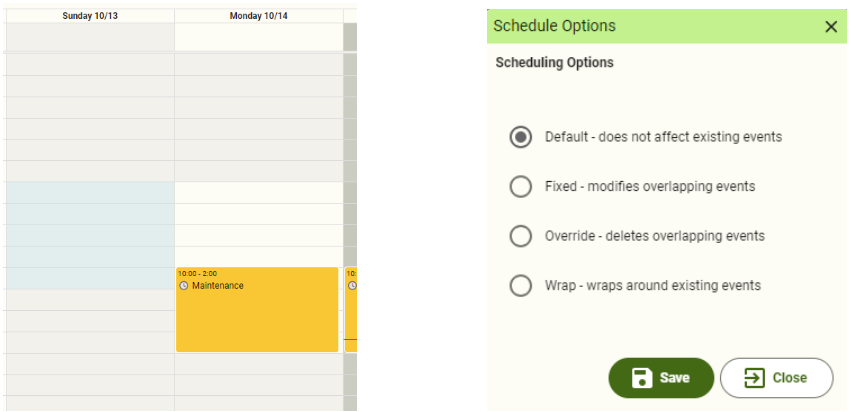

Intelligent scheduling allows a user to decide what to do when an operation they are trying to schedule overlaps with existing scheduled events. When the user attempts to schedule an operation that overlaps, or would overlap with an existing event after shift adherence is applied, they are presented with a popup with options on how they'd like to handle it.

Here, an event that overlaps with a maintenance event is attempted to be scheduled, prompting the schedule options popup to appear.

If shift adherence is enabled, then scheduling this event would cause the resultant start and end times to overlap with the maintenance event on Monday, which also triggers the popup.

Schedule Options

- Default - This operation will be scheduled as is, with no changes to itself, or any existing events that it overlaps with.

- Fixed - This operation will be scheduled as is and any scheduled events that overlap will have their times adjusted, in order to accommodate.

- Override - This operation will be scheduled as is and any scheduled events that overlap will be deleted.

- Wrap - This operation will wrap around any existing scheduled events. This may cause the operation to be split into several operations.

Filters

- Asset Selector: Click on the asset selector

to select which assets the scheduled events are shown for.

- Display mode: Scheduled events can be shown on a calendar or as a list.

- Period: Calendar or list can be shown for a month, week or day.

Adding Events

- In the calendar view, select the time you wish to schedule the event for.

- Click

button.

- Select the asset and type of event. If the event is 'Production' you can select a work order to be run or an item to produce or leave it just blank.

- Name the event, set start and end times, and add any relevant notes.

- For recurring events, click on the 'Does Not Repeat' link to edit recurrence options. Note events that have a work order associated with them cannot be recurring.

Orders

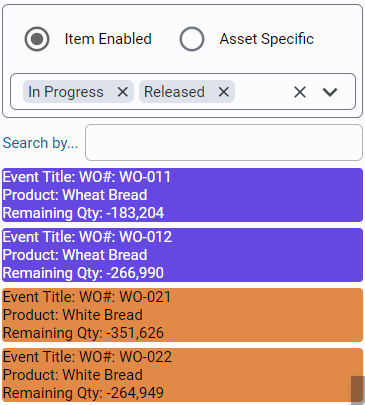

Orders can also be scheduled by clicking on the button in the top bar.

Set 'Item Enabled' to show production orders that can be produced on this asset. Setting 'Asset Specific' will ensure only orders that call out to be produced on this asset will be shown. Note: This primarily affects orders received from an ERP system where the asset has been specified.

Orders can be filtered by their status.

When an order is dragged onto the schedule, the total duration will be determined by the schedule rate (or standard rate if no schedule rate has been set) for this asset-item combo. The schedule and standard rate are set in the Materials Configuration page.

Note

Dragging an order may result in multiple events being scheduled at the same time. It is up to you to ensure that only one event exists at any time for an asset

for auto-scheduling to work correctly. The auto-schedule will only look at the first event scheduled when multiple events exist for an asset.

Editing Events

- In the calendar view, select the event you wish to edit and click

button.

Deleting Events

- In the calendar view, select the event you wish to delete and click

button. You can also use the 'Delete' key on your keyboard.