Operations Management

Understand how your plant is performing and where to focus continuous improvement efforts. Kanoa Ops includes everything needed for the day-to-day organization and operation of a manufacturing site, and tracks performance, OEE, and downtime to provide production insights and analytics.

Plant configuration is done entirely in-app, so qualified users with the proper permissions can make changes without extensive training or software expertise.

At a glance, Kanoa OPS provides...

- Asset Management

- Material Management

- Lot Management

- Production Order Management

- Shift Management

- Operations Scheduling

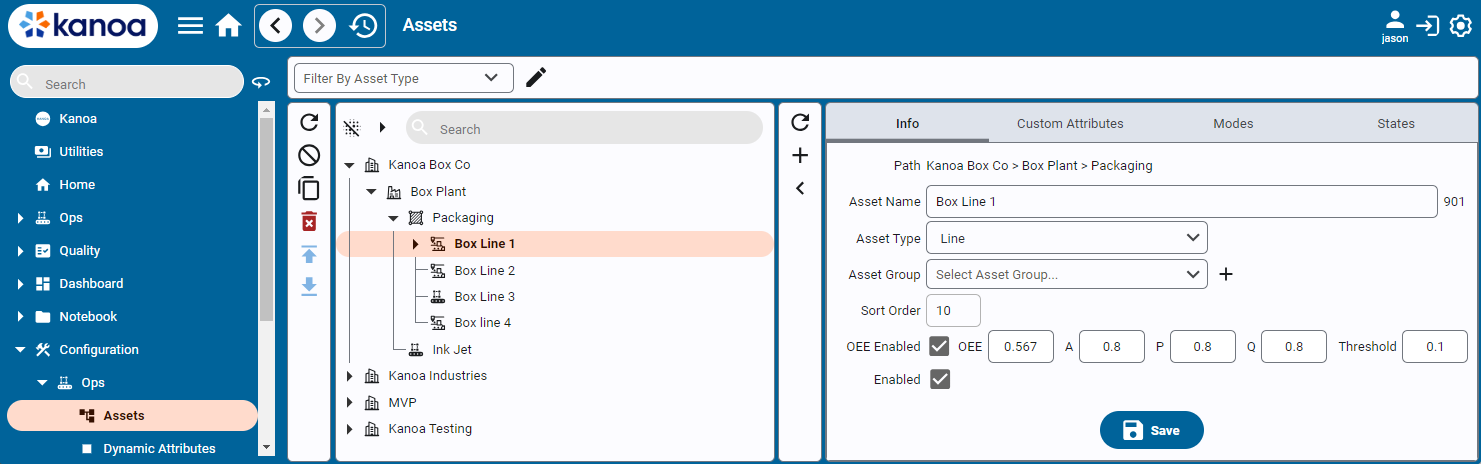

Configure Your Assets

For Kanoa Ops to provide valuable insights for your plant, it is important to define your assets, products, and processes. Kanoa Ops allows you to configure your enterprise's assets, modes, and states.

Click here to go to Asset Configuration

Connect Data

Kanoa Ops supports a variety of data connectivity options, making an extensible system that can grow to collect data from additional systems as adoption increases and requirements evolve. Machine Performance and OEE data can be collected via PLCs and automation equipment through Ignition's built-in OPC server or Industry 4.0 protocols like MQTT. Web APIs allow Kanoa Ops to integrate with business systems like ERP to automatically download material specifications and production schedules. When automatic data collection is not an option, Kanoa Ops provides manual entry solutions so that every single asset can be accounted for.

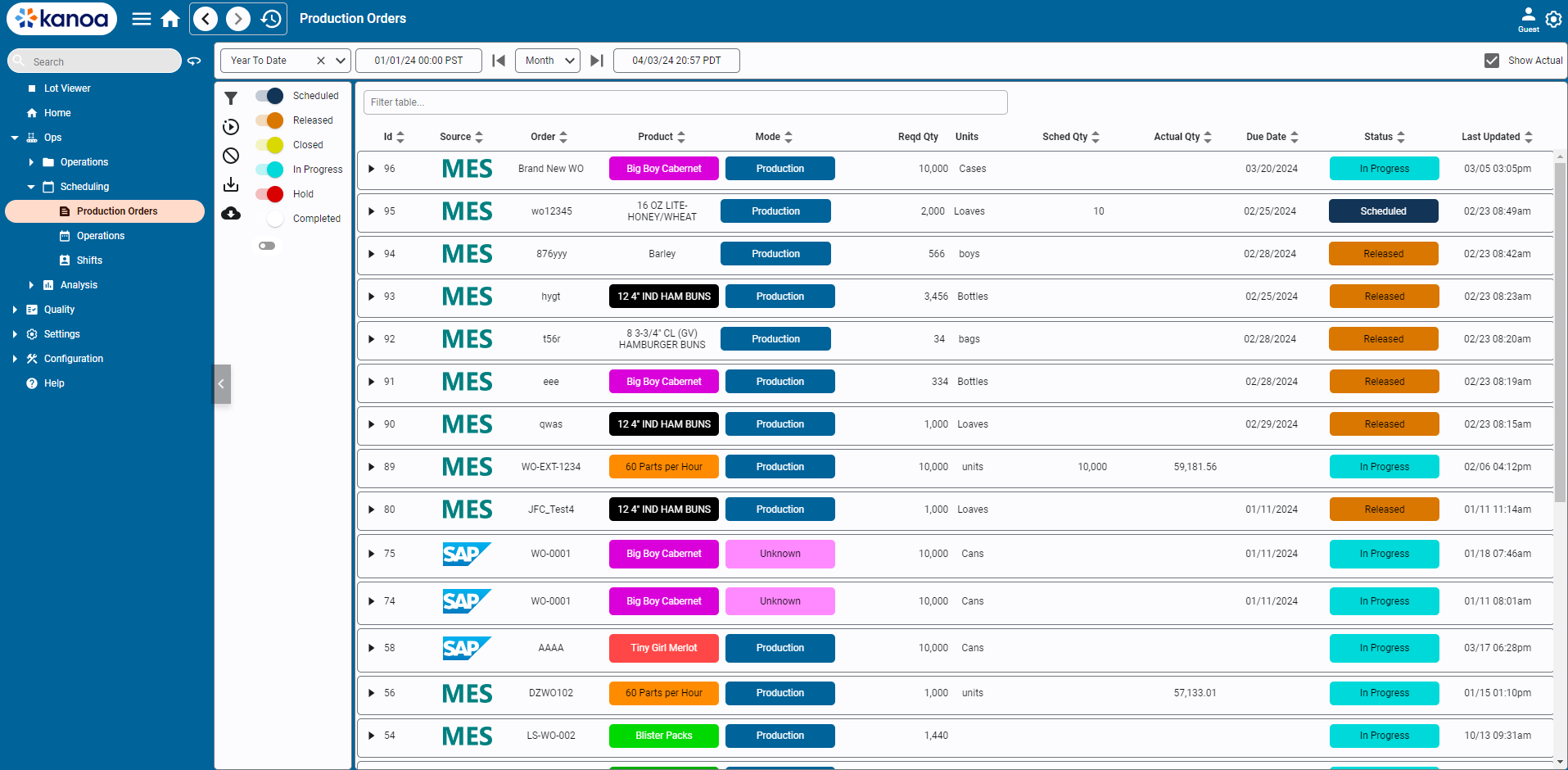

Manage Production Orders

Whether you call them work orders, production orders or batch tickets, our order management system allows you to create orders that can be scheduled or executed and then tracked. Orders can be created in the MES or pulled directly from your ERP or both.

Click here to go to Order Management

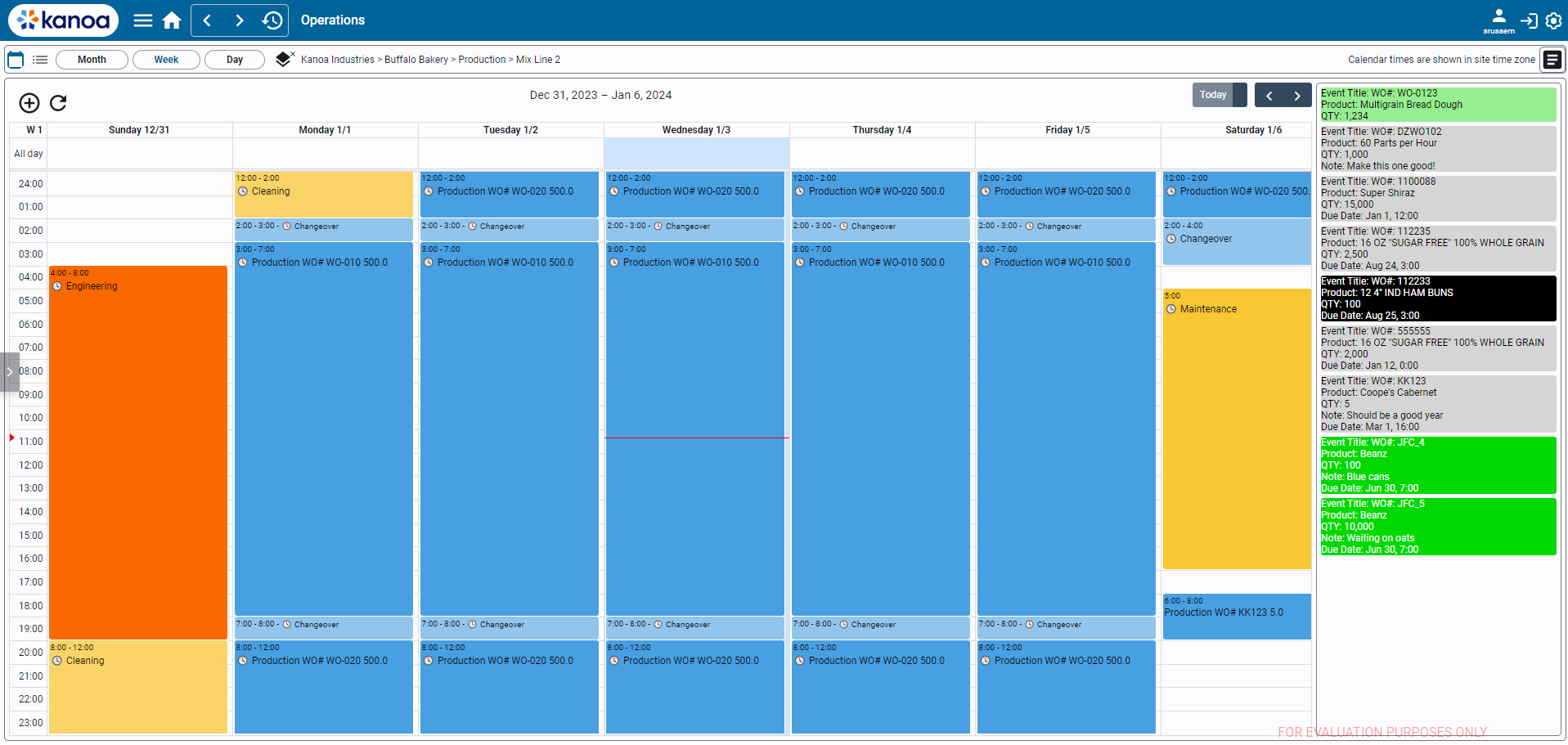

Schedule Work

Leverage Kanoa Ops and Ignition's Web Services modules to connect to Enterprise Resource Planning (ERP) systems for material scheduling data. Tie Kanoa Ops scheduling directly to ERP scheduling for a seamless integration; or pull work orders from ERP and do Detailed Operational Scheduling at the plant-level. Kanoa Ops also provides an interface for managing shift and crew schedules for additional data context. Kanoa Ops supports complex shift rotation patterns to reduce the manual work required to keep the system up-to-date.

Click here to go to Operations Scheduling

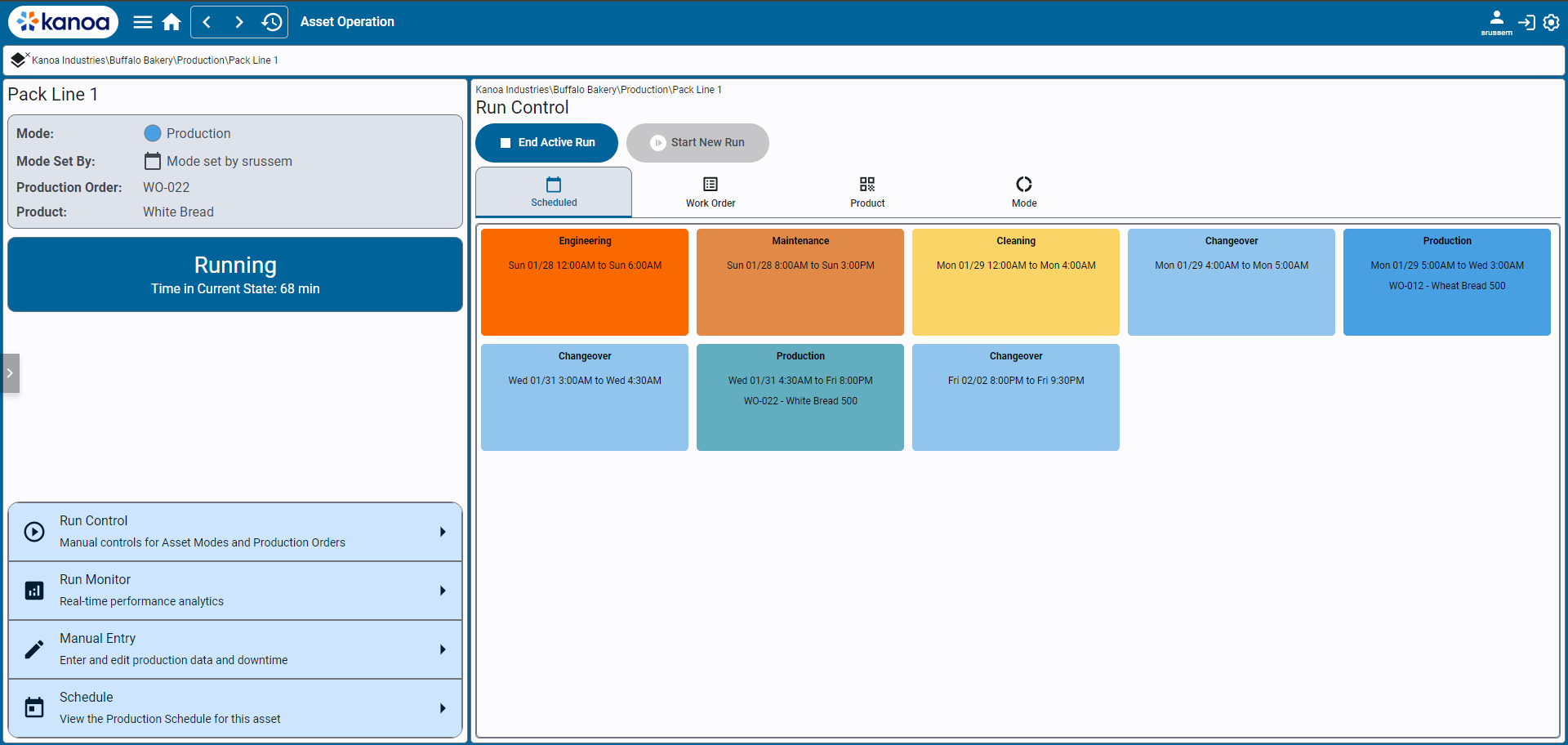

Operator Station

We've provided a ready-built Operator Station screen where your operators can select orders, view the schedule, execute operations and update production counts, or code downtime events. And it's entirely customizable!

Click here to go to Operator Station

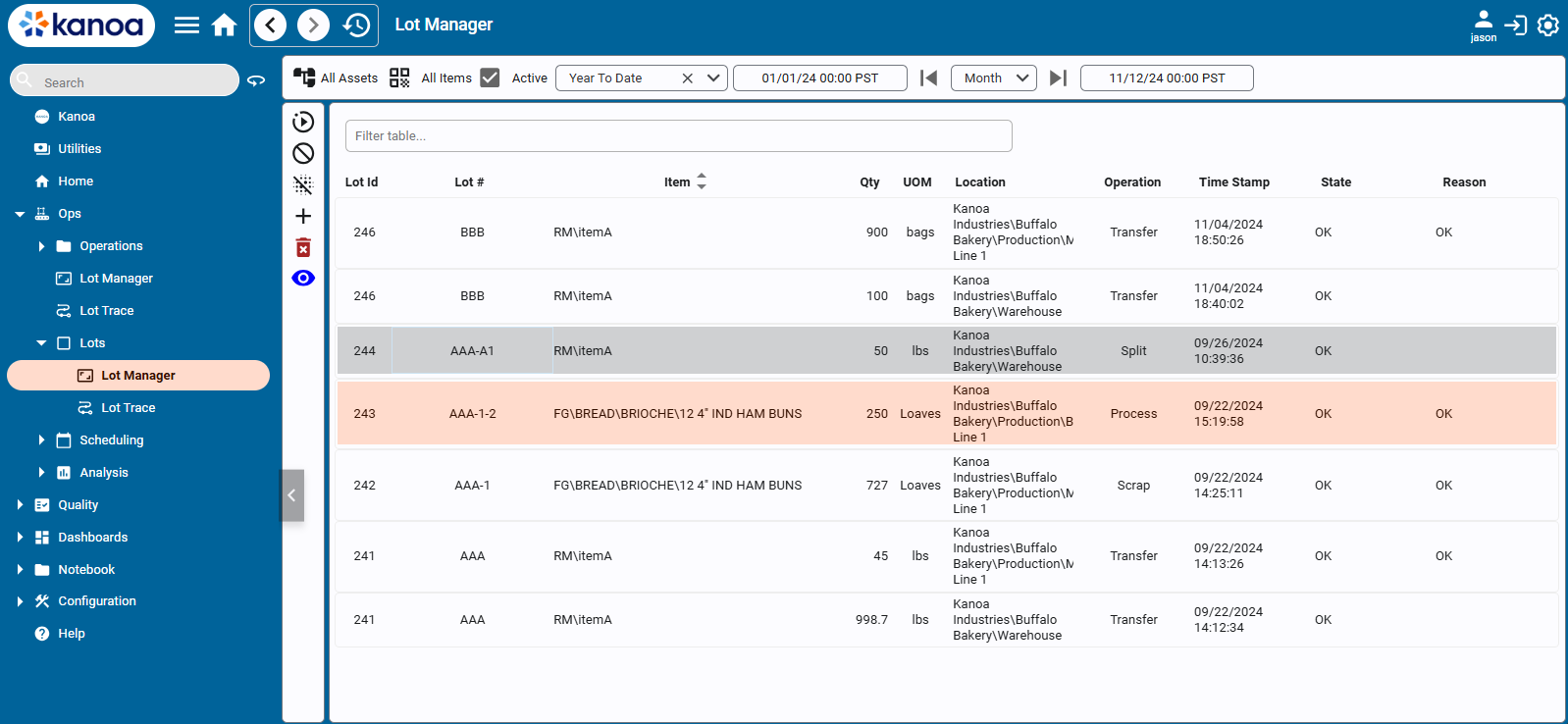

Lot Management

It’s important to know where your material lots are and how much material remains on hand. Kanoa Ops provides the ability to create material lots, associate them with operations and track them through your manufacturing process. This information can be shared with your ERP or Inventory Management System.

Click here to go to Lot Management