What is Kanoa MES?

Kanoa MES is a suite of smart manufacturing tools powered by Inductive Automation's Ignition platform. Kanoa's solutions are designed to equip your factory with new production management, analysis, and control tools that deliver value from day one and continue to evolve with your team and business.

What We Are

- We built our solution on top of Ignition to guarantee a highly flexible and customizable MES solution that works well with all your existing systems. Ignition provides all the tools necessary to connect to any type of data source and provides a development environment that allows you to easily customize the MES application to suit your needs.

What We Are Not

- A closed, proprietary solution with an egregious licensing model that can only be configured up to a certain point, and then forces you to change the way you do business or throw your investment away.

- A set of tools that leave you pretty much building a custom MES solution that is hard to support.

The Kanoa MES solution is comprised of a set of modules, a set of projects and a database.

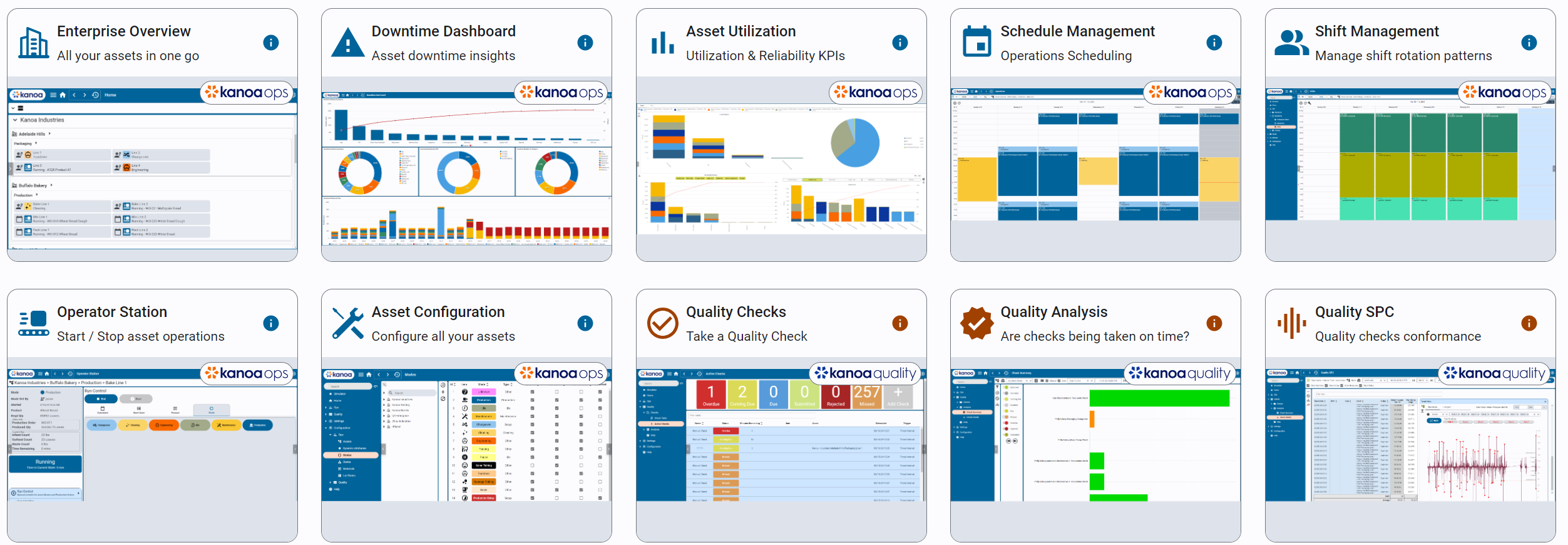

Kanoa Ops provides the key elements required for organizing and executing day-to-day manufacturing operations. Define your plant assets, products and materials, schedule operations, operators and shifts, execute production orders, code downtime events and analyze performance, OEE, and downtime to provide production insights and analytics, all from one application.

Kanoa Ops provides the following features:

- Asset Management

- Material Management

- Lot Management

- Production Order Management

- Shift Management with support for complex shift rotation patterns

- Operations Scheduling with recurrence rule support, auto-scheduling and intelligent scheduling

- Operation Analytics

- Web based mobile responsive application

- Themes support

- Language support

- MQTT data transfer between edge devices and MES Server utilizing built-in store and forward capability for a robust network solution

Kanoa Quality provides a comprehensive digital system for managing manufacturing quality. Users can create check sheets that describe all of the quality checks that may be required at any point in the manufacturing process. These check sheets can be scheduled based on manufacturing operating conditions like product changeovers, shift changes, machine mode changes, or timed intervals, or triggered by asset events such as alarms, counts, or runtime. When a quality check is scheduled to be executed, the checks are presented to the operator with instructions, so they can enter quality data manually and validate any automatically collected data.

Quality engineers get a holistic view of all the quality checks that are pending, due, in-progress, complete, or late; so they can take action to make sure tests are getting done. Kanoa Quality also provides analytics on both the adherence to scheduled quality checks and the data collected from those checks.

Kanoa Quality provides the following:

- Environmental, Safety, Operations and Product Quality Management

- Quality Check creation

- Automatic scheduling of quality checks

- Provides procedures and instructions for taking quality checks

- Storage and data management of quality check data

- Analytics and third-party audit reporting

- Management of product and manufacturing process tolerances

- Alarming and email notification on failed checks

Startup Guide

New to Kanoa? This guide will show you how to get KanoaMES up and running at your factory.

System Architectures

Clearly, an MES implementation for a multi-site or multi-asset company will require a slightly different architecture than that of a company with a single production line. System constraints and requirements are also going to dictate what that architecture looks like. Check out our architecture page for information on all the options available and what we recommend.

System Functions

Want more help on our system functions? You'll find all of them documented in the appendix along with examples.

Want to join us as a partner? Our partner program welcomes systems integrators who actively use and improve our product offering.

Our partners create a network of technologies, thought leaders, and solution providers to solve any manufacturing challenge.

For more information on joining us, visit our Friends Of Kanoa page.